IGBT power die bond

The models SV350 was equipped with high precise driving systems and multiple feeding systems, it can flexibly meet the requirements of IGBT multiple chips (dies) bonding simultaneous.

4 bonding heads

SV350 was adopted 4 bond heads helps to increase the production efficiency and provides more favorable conditions for pick up multiple types or more materials at each placement cycle.

Multiple feeding system

SV350 was adopted with multiple feeding system such as Auto-Wafer, Auto-Tray, SMT tape feeders, Solder plate tape feeder, and Bulk-pack feeding platform (option).

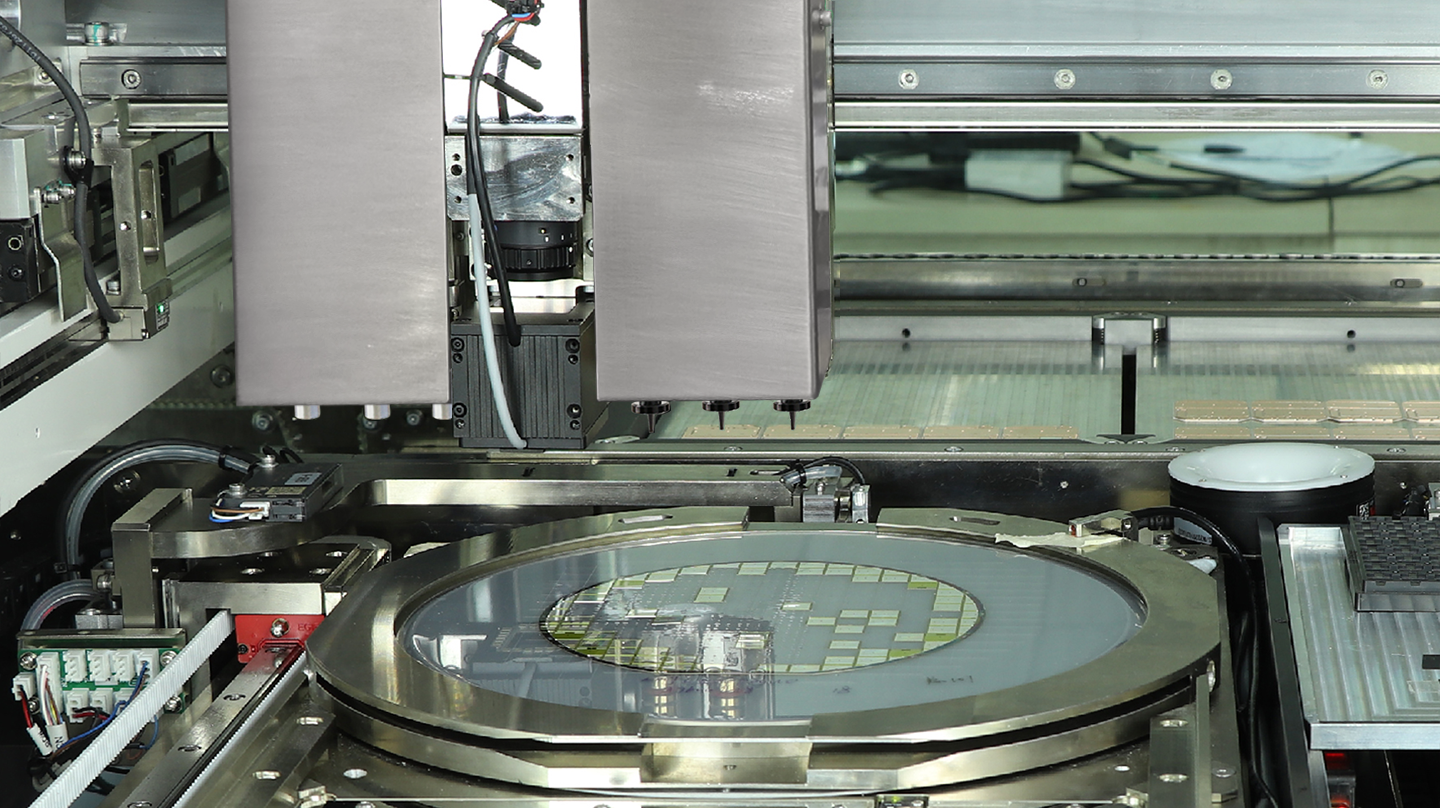

Auto-Wafer system

Auto-wafer system adopted with a wafer flange cabinet, the max. capacity is 13 wafer flanges of 8 Inch wafer (for flange diameter is 293mm), compatible max. 5 die wafer types of bonding simultaneous

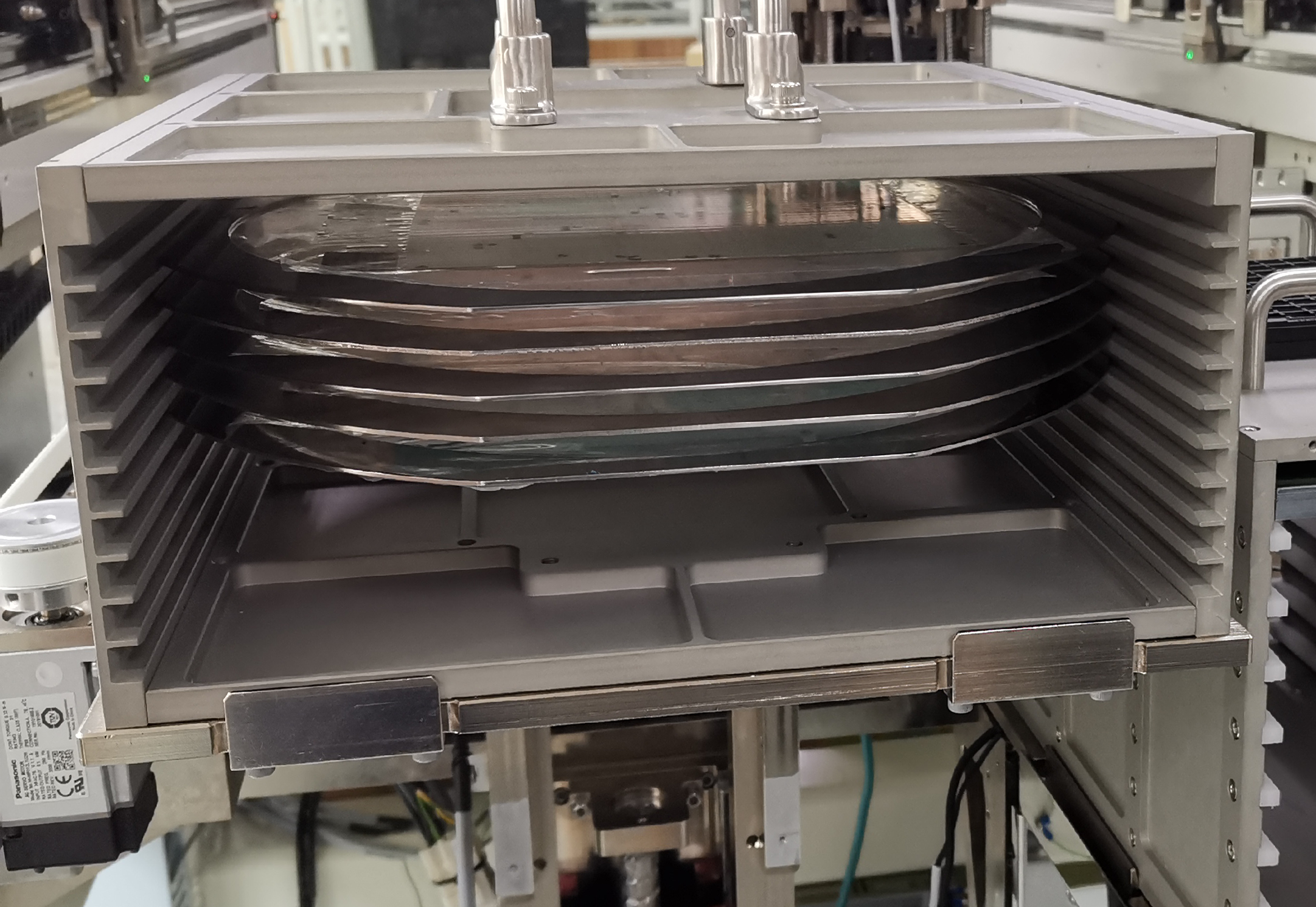

Auto-Tray system

Auto-tray cabinet capacity is max. 8 tray cassettes, tray cassettes capacity max. 120x250mm or 120x120mm x 2 trays (component height max. 10mm), compatible max. 5 types of components (tray forms) of bonding simultaneous

Tape feeder platform

Up to 8 Tape Feeders or two set of Solder-plate tape feeders, compatible the HT2-14 / HT12-26 / HT22-36 types of Solder-plate feeder (for solder-plate size: 2x2~14x14mm / 12x12~26x26mm / 22x22~36x36mm)